Tenth Generation: 1997-2004 F150 Brake System

Tenth generation model F150 pickup trucks were available with two choices of brake systems: a classic disc/drum setup and a four-wheel disc option. A disc/drum setup, using 12.13” (308mm) rotors in the front and 12.75” drums out back, was found mainly on standard cab base models. The hydraulic wheel cylinder used with a drum has a 1-inch bore that actuates a set of 11”x2.25” brake shoes. OEM material for the brake shoe is an organic type.

F150 pickup trucks equipped with four-wheel disc brakes had the same 12.13” rotors in the front and saw larger 13.1” (334mm) discs installed at the rear. Front calipers are a twin-piston design utilizing a 48 mm metal piston (this caliper was used on both disc/drum and four-wheel disc setups). Rear calipers use a single 51mm metal piston. Front and rear pad material were semi-metallic.

In terms of master cylinder, trucks with cruise control were equipped with a 1-1/8” bore master cylinder whereas those without had a slightly smaller master cylinder with the bore measuring at 1-1/16”.

Eleventh Generation: 2004-2008 F150 Brake System

As the towing and payload capacities increased with the introduction of the eleventh generation F150 in 2004, so did the size of the brake system. The disc/drum setup was dropped entirely and solely a four-wheel disc setup is available.

Front rotors, cast-iron vented, were upgraded to 13” and the rears, cast-iron solid rotors, even bigger at 13.70”, respectively. Calipers were also bumped up in size and now the front, still using a dual piston configuration, have been upped to 54mm and the rear (still single piston) 56mm. Original equipment brake pads use a metallic compound as their friction material.

In the world of muscle cars, having bigger brakes on the rear is unheard of, as most of the stopping ability is provided by the front brakes as a car pitches forward during deceleration. When examining a truck, however, larger brakes at the back end does make sense given an F150’s utilitarian nature. Carrying cargo in the bed or pulling a trailer increases the weight over the rear axle (not to mention the gross weight of the vehicle itself) and thereby must be counteracted with bigger rear brakes to assist with the greater load on or behind the rear wheels.

The master cylinder for this generation remains with a 1-1/8” bore, however, it is not the exact same cylinder in terms of port location and thread sizing.

Twelfth Generation: 2009-2014 F150 Brake System

Whilst the twelfth generation of F150 production officially kicked off in 2009, it wasn’t before 2010 that the trucks saw a change in the braking system. Thus the 2009 F150 braking system remains the same as 2008.

2010-2018 F150 trucks had their front rotors upsized once more, now up to 13.8”. The rear rotors, cast iron and vented, retain a diameter of 13.7”. The calipers did not change and a dual 2.13” piston design is still responsible for clamping up front and a single 2.13” piston caliper at the back. OEM pad material is a non-asbestos organic type.

Even though several new engines have been introduced into the F150 lineup since 2010 (and technically, a new generation of F150 was released in 2015), the brake system remains the same as above.

The Workings of the Brake System

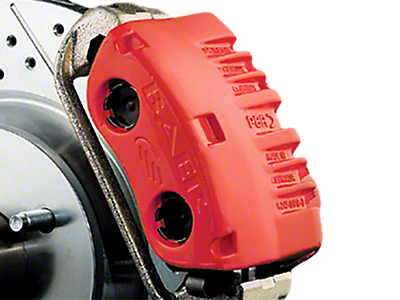

The brake system on an F150 pickup is hydraulically actuated and assisted with engine vacuum. When you depress the brake pedal, fluid is displaced from the brake master cylinder and out toward the calipers. As fluid is non-compressible, the fluid, channeled through the brake line to the caliper, exerts pressure on the inner side of the caliper piston. This presses the piston out of its bore in the caliper and squeezes the brake pads against the rotor.

The friction between the rotor and brake pad is what slows the truck down. The greater the force applied to the caliper, the faster the truck will decelerate. Brake force is modulated by how far you push the brake pedal. Pushing down further on the brake pedal increases the pressure applied to the rotor. Engine vacuum assists with this process and provides the necessary pressure boost in order to operate the brakes.

If there was no assist with the brakes (i.e manual brakes) all the braking force would have to be generated and felt by the driver. (Notice how the pedal is always very firm when the vehicle is off, but as soon as the engine starts the pedal force lightens? This is due to the vacuum assist only being available when the engine is running. With the engine off the brakes are essentially a manual system and all braking force is produced by your leg).

In the case of a drum system versus disc system, the operation is essentially the same. Instead of a caliper squeezing the pads on a rotor, a drum system houses a hydraulic wheel cylinder inside the drum. When the pedal is pressed and this cylinder is actuated, a plunger on each side of the cylinder presses the brake shoe up against the drum.

F150 Brake Maintenance

Brake rotor and pad changes are regular maintenance items that should not surprise anyone. Brake fluid, on the other hand, is another potential brake-related maintenance event that is easy to overlook. Now, the reason I say “potential maintenance event” is because Ford does not actually specify a certain mileage or time interval in which to flush and replace the brake fluid. Brake fluid can be a lifelong fluid, however, it can also become contaminated, boil off or absorb water, all of which will make the braking system less effective. Thus flushing the brake system and replacing with new fluid is left up to each owner on a case-by-case basis. Certainly if done correctly, flushing the old fluid out and replacing with new cannot hurt the brake system. Trucks that work hard and/or in harsh climates are likely to eventually suffer from deteriorating brake fluid.

While on the topic, 1997-2003 Ford F150s call for DOT 3 brake fluid. All models after that call for DOT 4 brake fluid. DOT 4 brake fluid is backward compatible with DOT 3 and thus can be safely used in a DOT 3 system without negative consequence (but don’t do the opposite and put DOT 3 fluid in a DOT 4 system). The main difference between the two is the additive package that results in DOT 4 fluid having a higher boiling point (which is certainly advantageous). The correct amount of brake fluid is simply to keep the brake fluid at or above the minimum line and at or below the maximum line as indicated by the reservoir.

F150 Brake Upgrades

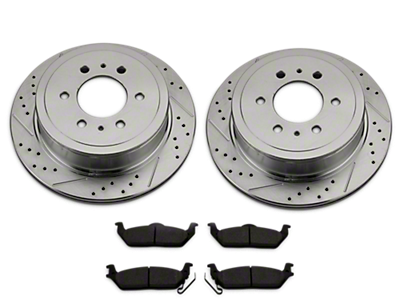

For owners who are looking to upgrade the factory brakes on their F150, the most beneficial thing you can do for your dollar is to combine a good rotor with a good pad. Cheap rotors wear poorly and warp easily. Given the weight of an F150 plus whatever it may be hauling in the bed or towing behind it, the factory brake system will be subject to a lot of abuse. A cheap pad and rotor will suffer from heat deterioration and not only wear out sooner than expected, but also lead to poor braking performance.

If your truck will be subject to heavy duty hauling or towing, semi-metallic or metallic pads are a good material to go with. While these are without a doubt the harshest material on a rotor, they work very well given the higher gross vehicle weight of an F150.

Shop All Truck Brakes

Fitment Includes:

- 1997, 1998, 1999, 2000, 2001, 2002, 2003, 2004, 2005, 2006, 2007, 2008, 2009, 2010, 2011, 2012, 2013, 2014, 2015, 2016, 2017, 2018, 2019, 2020, 2021, 2022, 2023 and 2024 F150s

- Base Model, XL, XLT, Lariat, Lightning, King Ranch, Harley Davidson,STX, FX2, FX4, Limited, Platinum, Raptor

- 2.7L EcoBoost, 3.5L V6, 3.5L EcoBoost, 3.7L V6, 4.2L V6, 4.6L V8, 5.0L V8, 5.4L V8, 6.2L V8

*Please see product pages for any exceptions.