Exhaust Headers Guide: What to Know Before You Flow

One of the great ironies in this industry is that possibly the most nuanced system on your car is also considered one of the most accessible and commonly modified things on any vehicle. Any shadetree mechanic with a wrench and a 6-pack can do exhaust work, but when you’re dealing with off the shelf parts, the subtlety and science of making a good exhaust system is lost on most.

Exhaust Headers vs Exhaust Manifolds

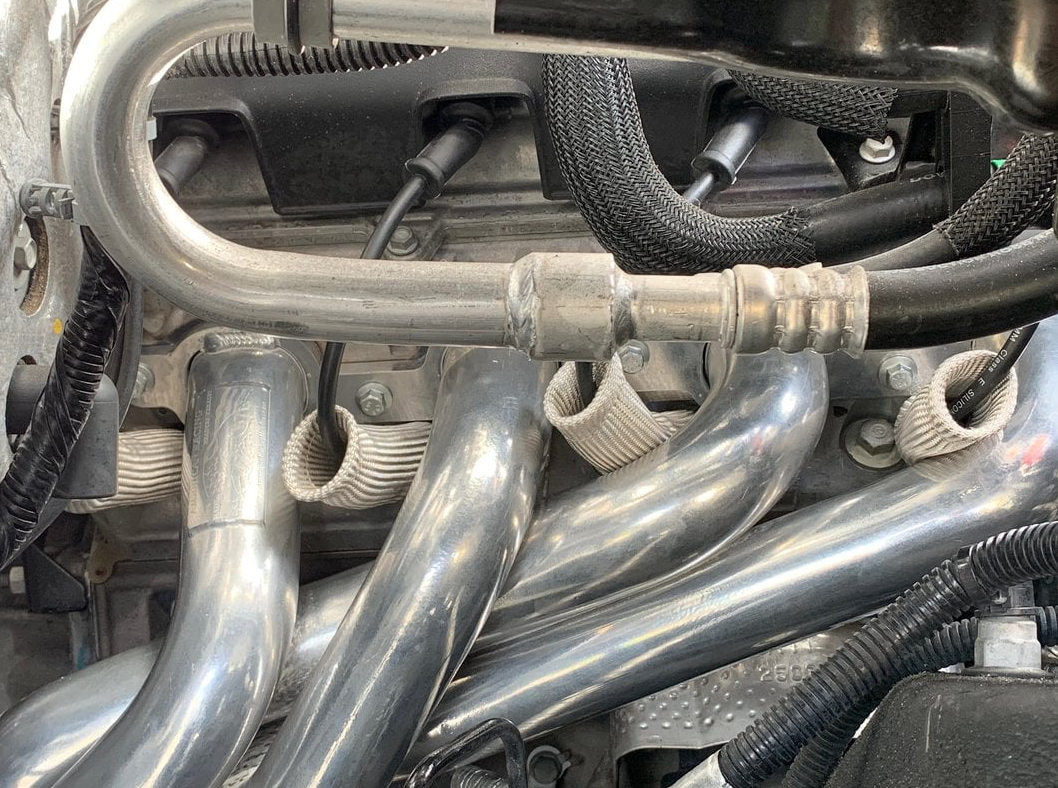

This is a common question that gets raised whenever headers come up. Why is it that the stock components are usually referred to as manifolds, but aftermarket versions are called headers? While they do the same job, the difference is that an exhaust manifold is a solid cast iron piece across all cylinders while an exhaust header is made up of individual steel tubes for each exhaust port, welded to meet at a collector or several collectors to bring the exhaust gases down to a single pipe, ready to flow through the rest of the exhaust system.

Manufacturers use exhaust manifolds for a few reasons, but the two main ones are that cast header blocks are cheaper to produce, and the fact that these thick cast iron structures are great for holding in heat, are very durable, and help keep unwanted exhaust noise down. There is always a big struggle to keep temperatures down in the engine bay, especially with how much sensitive wiring is snaking around all over the place in modern vehicles. The drawbacks of these manifolds mostly come down to two fundamental issues:

- Rough interior surfaces from casting results in poor exhaust flow

- Unequal length of exhaust travel for each cylinder to meet at the collector

The first issue is taken care of pretty easily. Since exhaust headers are made from smooth bore tubing, there is very little to disrupt the exhaust flow. The second issue gets a little more complicated, and first, we need to talk about scavenging.

What is scavenging, and how do equal length headers help?

Basically, scavenging can be thought of as the opposite of backpressure. With efficient exhaust flow, the outgoing gases will create a vacuum behind the outgoing pulse. As the valves are opening between cylinder strokes, there is a sweet spot where the intake and exhaust valves are at least partially open at the same time. During this brief moment, that vacuum will actively pull in fresh air through the intake valves resulting in an effect not dissimilar to what you would get from mild forced induction.

More air in the cylinder means more power, and more power means more smiles. Two things happen once you exhaust valves open; first is a high-pressure shock wave caused by the rapid expansion of hot exhaust gases as they exit the valve, traveling at the roughly the speed of sound. Following behind that is the actual burst of exhaust gases, which will ideally be unimpeded in exiting the headers through the collector into the rest of the exhaust system.

Once this shockwave reaches the end of the pipe and equalizes to atmospheric pressure, a low-pressure wave is sent back up the tube to the cylinders to pull that air through the cylinder.

Where equal length headers come into play to help here, is by ensuring that each the tube from the cylinder head to the collector is the same length, those exhaust pulses have the same distance to travel to get there. That way, there is always a clear path for the exiting exhaust to free up as much back pressure as possible for the next pulse coming back down that line, ensuring as close to ideal conditions for scavenging as possible.

This is where the main advantage of headers come from, and why there is usually such a large performance benefit in installing them. Another thing to note is that a bigger header tube isn’t necessarily better. The process of scavenging relies on the vacuum created in that pipe, and too large a diameter would limit that effect. This is why engines actually make more power with headers on than if they just vented straight to atmosphere directly from the cylinder head.

What’s better, shorty or long tube headers?

That depends. First of all, if you’re running a turbocharged car, long tube headers aren’t usually feasible or practical, so these cars will usually have shorty headers that feed right into the hot-side inlet of the turbo. Otherwise, long-tube headers are generally considered to be the best for reducing back pressure as much as possible, and therefore the best for scavenging — this is despite the fact that they actually technically flow less than shorty headers generally do, but after the section above, we have a good understanding of why that is.

Another advantage with long-tube headers is that they not only give solid peak power numbers, but help to raise horsepower and torque in the low and mid-range of the RPM band, giving you more usable power down where you usually need it. This makes for a more fun drive day to day, as you’re rarely able to enjoy wide-open throttle out to redline out on the street.

The disadvantage comes in the form of packaging. Some cars are worse than others, but it can be difficult to route that big cluster of tubes out of the way of motor mounts, the firewall, the transmission, and still have ground clearance for them afterwards. Meanwhile, not only do short-tube headers make packaging easier, they also are generally designed to bolt right up with your stock exhaust, allowing you to easily bolt in a set of headers without having to worry about custom fabrication or having to move stock emissions equipment like your catalytic converter(s), which can get legally messy in some states.

Brands to keep an eye on:

There are of course a ton of good companies out there making great headers, but many of these companies focus on specific categories of car, or brands, so it’s difficult to recommend one and be sure that they will have options for the general reader. That’s why I’ll just be focused on the major brands in the space that are most likely to have something for your car, and can be trusted to do good work.

- Kooks Headers: Borne out of the hot rod golden era in the 1960s, Kooks Headers have been the gold standard in racing for decades. Every set of headers they sell is designed and manufactured right here in the USA, and that dedication to their craft shows in the quality of their product. They aren’t usually the cheapest option, but they’re among the best you can buy.

- PaceSetter Exhaust: With one of the widest application coverage, and quite a few options available for many makes within that range, you’re bound to come across PaceSetter in your hunt for performance headers. Especially with their line with built-in catalytic converters. Their headers are built in the USA and offer competitive warranties as well. Hard to go wrong here.

- Corsa Performance: Not too many companies can sell you an intake and complete exhaust kit, but Corsa has excelled in the industry for over 20 years. With solid vehicle coverage, solid warranties, bolt-on installation, and surprisingly low pricing given the quality, these guys are a no-brainer.

- JBA Exhaust: Especially known for their Cat4ward series headers, JBA is a great option for quality headers at a range of price points to fit your budget. They offer a range of finish options from Nickel-chrome plating to stainless steel, ceramic coating, and even titanium ceramic coating to give you options to fit your needs as well as your budget.

- Flowmaster: You can’t talk exhaust without Flowmaster coming up. They’re known mostly for their mufflers and cat-back kits, but Flowmaster doesn’t seem to do anything poorly, and if anyone knows exhaust, it’s these guys. Their Scavenger series is a prime example of equal length headers done right, even in short-tube form.

- Doug Thorley Headers: For over 60 years now Doug Thorley has been setting the standard for high-performance headers. Now with an emphasis on compatibility, all of their headers are built to meet 50 state emissions standards, are compatible with factory O2 sensors, made in the USA, and every one of their headers carries a lifetime warranty.

Anything I missed, or do you have any questions about your setup? Drop a comment below, and I’ll get back to you!