Understanding the Components of Dodge Dakota Vehicles With an extensive range of different automotive parts, understanding the components that constitute Dodge Dakota vehicles can be a challenging yet intriguing venture. A typical Dakota exhibits a vast array of assembly parts working in unison, including, but not limited to, the engine, transmission system, suspension system, braking system, exhaust system, and internal accessories such as GPS or entertainment systems. Thus, understanding the function of each part is essential in ensuring the vehicle remains in its optimal performance state.

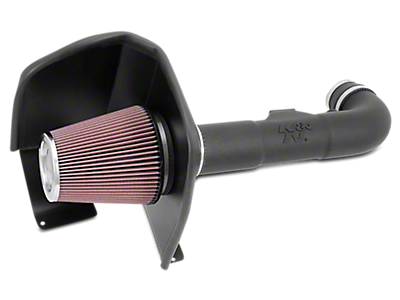

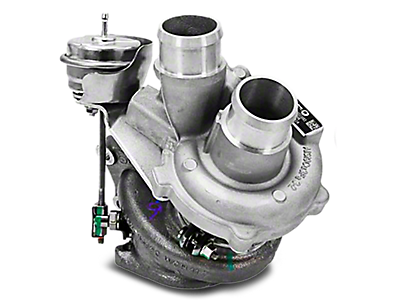

The Engine

Beginning with the engine, it serves as the heart of any Dodge Dakota, converting fuel into mechanical energy that drives the vehicle. Engine parts are predominantly made of cast iron, steel, or aluminium due to their high heat resistance and strength. Manufacturing processes of such components typically involve processes such as casting, machining, and forging. Environmental conditions, the vehicle's age, mileage, and maintenance history significantly affect the engine's longevity.

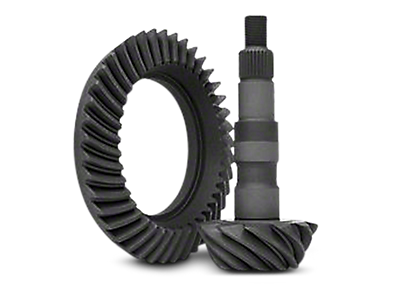

Transmission Systems

Simultaneously, transmission systems provide adequate power to the vehicle wheels at a given speed. Steel is a common material for its construction, and gear cutting and hobbing are frequently employed manufacturing techniques. Quality standards for transmission parts are exacting, necessitating precise machining, balancing, and measurements.

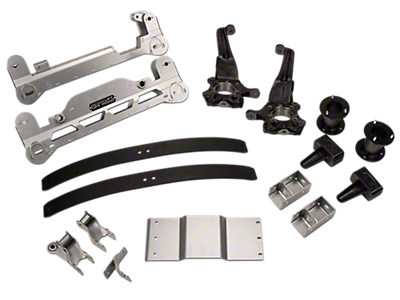

Suspension Systems

Suspension systems on the other hand, are designed to maximize the friction between the tires and road surface, therefore providing steering stability and a comfortable ride. Depending on the particular design, materials can vary from steel, cast iron, to aluminum, and rubber for bushings. Such systems are built through processes like casting, forging, and welding. It's important to note that a worn-out suspension system compromises a vehicle’s optimal performance, making its replacement a top concern, particularly for older vehicles.

Braking Systems

Meanwhile, braking systems, essential for vehicle safety, consist of various components – including brake rotors, pads, calipers, lines, and fluid – all working in tandem to slow or stop the vehicle. Brake parts must exhibit high heat resistance and durability, hence typical materials include composite ceramics, semi-metallic compounds, and cast iron. Specific quality standards must be followed to ensure the highest level of safety. Moreover, choosing between OEM (Original Equipment Manufacturer) and aftermarket parts can be determined by considering factors such as the vehicle’s age, mileage, and the owner’s preference for performance versus cost.

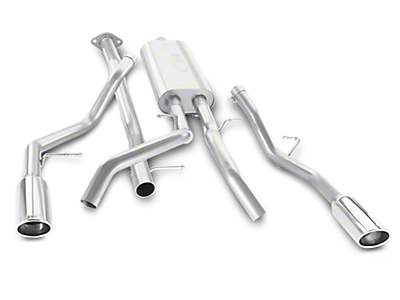

Exhaust Systems

Exhaust systems divert exhaust gasses emitted from the engine, thus controlling the noise and ensuring the engine runs efficiently. Mostly made from stainless or aluminized steel, manufacturing processes involve pipe bending, welding, and heat shielding. Replacement considerations typically hinge on rust and corrosion due to exposure and age, exhaust leaks, and state emission requirements.

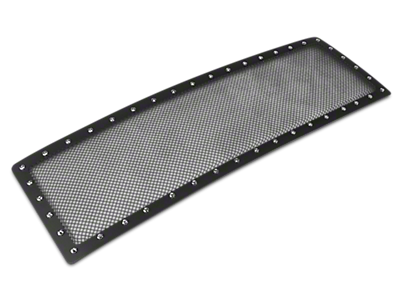

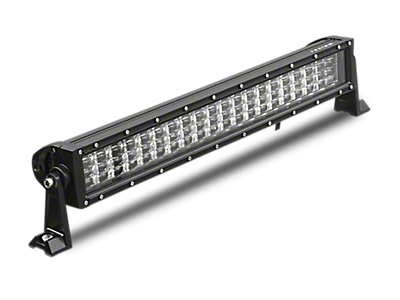

Accessories

Lastly, a modern Dodge Dakota wouldn’t be complete without a sophisticated suite of accessories, often electronic in nature. GPS navigation systems, entertainment setups, and automated safety measures form an extensive list of parts that can significantly upgrade the experience of every ride. Given the diverse range of models and configurations for Dodge Dakotas over the years, compatibility is a rigorous concern when selecting accessories.

Aftermarket Components

Aftermarket components can bring significant advancements in performance or drive comfort. Thus, it is crucial to understand each part's function, its manufacturing process, and the materials used. Equally important is bearing in mind the factors – age, mileage, operating conditions, and maintenance history – that impact the longevity of these parts. Armed with this knowledge, one can then make well-informed decisions about aftermarket part purchases by meticulously researching the product's technical specifications and ensuring that it meets the appropriate quality standards. Thus, keeping a Dodge Dakota running smoothly can indeed be a rewarding exercise in precision and knowledge.